Bundled Colored Wires Pink Purple White Green

Contents

- Types of Wire Color Codes

- Wire Colors for DC Power

- AC Power (120/208/240 Volts)

- 277/480 Volt Wire Color Standards

- Data Wiring

- Labeling Electrical Wires & Conduits

- Effective Training Options

- Applying Color Standards to Existing Wiring

Oct 18, 2017

Electricity is an essential component for virtually every step in manufacturing and most other industries. In most facilities, the electricity will come in at one point in the building, and then be distributed to just about every corner through a series of wires. Even the tools and machines that are used are filled with wires that are used to conduct the electricity to perform whatever action is needed.

While electricity is used constantly throughout the day without much thought, it actually has the potential to cause many issues. If something is not wired properly, it can result in injuries, deaths, fires, and many other problems. This is why there are well-established wire color codes to ensure those working with an around this type of equipment can ensure everything is wired safely and effectively.

There are quite a few different wire color code standards in place, so it is important to understand which one to follow in which situation. The standards used will vary based on what country the wiring is being done in, and the type electricity it is for, and other factors. Learning about the different options that may be used in a given situation is essential for workplace safety.

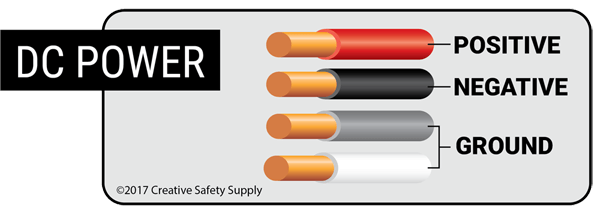

When wiring for DC power, there are typically going to be either two or three wires. The coloring is as follows:

- Positive - The wire for the positive current is red.

- Negative - The wire for the negative current is black.

- Ground - The ground wire (if present) will be white or grey.

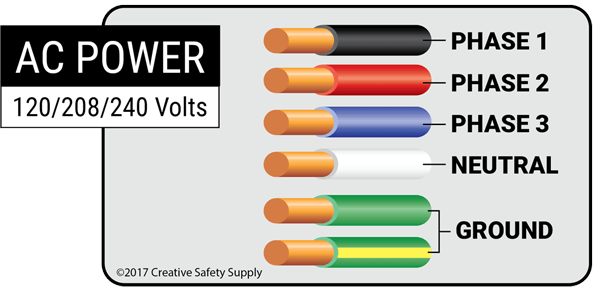

AC power comes in many different types based on how many volts the wires will be carrying. For wires that will be 120, 208 or 240 volts, the following wiring color standards are used. It is important to note that with this type of wiring, there are multiple phases in place, each of which will get its own color wire to make it clear what it is for those working on it.

- Phase 1 - Phase 1 wiring should be black.

- Phase 2 - Phase 2 wiring should be red.

- Phase 3 - Phase 3 wiring should be blue.

- Neutral - Neutral wiring should be white.

- Ground - Ground wiring can be green or green with a yellow stripe.

In some uncommon situations, one phase will have a higher voltage than the others. These are known as high-leg connections. While rare, they can be identified by looking for a wire that is marked with orange, which will be the higher voltage wire.

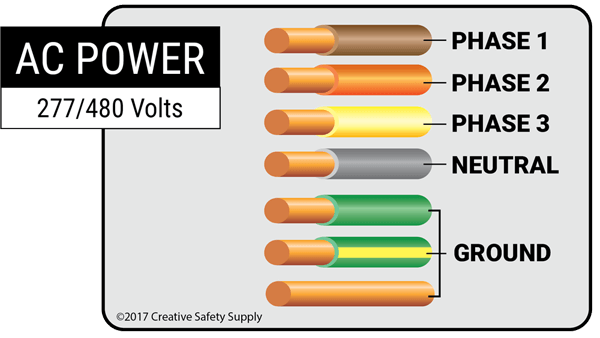

These high-voltage connections are quite common in many manufacturing and other industrial areas. Due to the serious potential for deadly electrocution or other issues, getting these color codes right is essential.

- Phase 1 - Phase 1 wiring should be brown.

- Phase 2 - Phase 2 wiring should be orange.

- Phase 3 - Phase 3 wiring should be yellow.

- Neutral - Neutral wires should be grey.

- Ground - Ground wiring should be green, or green with a yellow stripe.

These are the wire color coding standards that are used in the United States. In Europe and other countries, there are different standards in place. In most cases, a machine made overseas for use in America will be wired according to US color standards. Taking the time to confirm this is the case before using the machinery is always a smart safety step.

Another important thing to keep in mind when looking at the safety of electrical wires is the data wiring in a facility. Cables that are used to transmit data for computer systems are often thought to be harmless since they are carrying information rather than electricity.

Some types of networking cables will have enough electricity flowing through them to cause a hazard. Certain devices, such as phones, will just need the 'power over Ethernet' which means they get the electricity that is needed from the network cable they are connected to. If someone cuts into these wires, or they become frayed, they can present a risk of shock or fire.

Data cables are typically colored based on the needs and standards of the facility rather than the electrical standards due to the lower voltages. Applying labels or warning signs near these types of cables can serve as a good reminder of the potential risk of shock.

The wire color codes used are only going to apply to the actual wires that are carrying the electricity. In many cases, a bundle of these colored wires will be grouped together, and sealed within a black or grey cable. This helps to protect people from accidental exposure, and makes it much easier to run the wiring where it needs to go, especially for higher voltage situations.

When this is the case, it is important to take the time to properly label the wires and electrical conduits to warn people of potential dangers. Using an industrial label printer, it is easy to identify every set of wires with information about how much electricity is present, where the wiring is coming from, and where it is going.

Placing warning signs anywhere that someone might interact with electrical wires, especially high-voltage wires, is another good idea for improving overall safety. These signs can serve as a good reminder to those in the area that there are dangerous wires present. There are many signs that can be used depending on the specific situation.

Those who work directly with electrical wiring on a daily basis will need to be initially trained on what each of the wiring color codes means. Once they are performing their job regularly though, it will become like second nature to them.

Those who don't work directly with wiring all the time also need to get this type of training, and in many ways it is even more important. Without proper guidance, training, and documentation, they could put themselves or the entire facility at risk if they need to interact with wiring in any way. Anyone who will have any exposure to electrical wires should have at least a basic understanding of the wire color codes.

Perhaps more important than the direct training is going to be making sure that everyone knows where to go to reference the color codes. Facilities should have some sort of reference material, which could be a poster, a book, a computer system, or any number of other things. However the information is conveyed, it needs to be easily accessible so people can find when it is needed.

If there are wires in a facility that were put in place prior to the standards that are now used, it is important to take steps to address this safety concern. One option is to remove and replace all the wiring in the facility. Older wiring may have other safety related issues, so this can be a good solution in those situations.

If that is not possible, applying wire labels every few feet is another way to convey the necessary information that would otherwise be indicated by the color of the cable. This can be a good, affordable solution for bringing older wring up to a better safety standard.

Resources

- https://www.allaboutcircuits.com/textbook/reference/chpt-2/wiring-color-codes-infographic/

- https://www.treehugger.com/sustainable-product-design/big-steps-in-building-change-our-wiring-to-12-volt-dc.html

Similar Articles

Bundled Colored Wires Pink Purple White Green

Source: https://www.creativesafetysupply.com/articles/wire-color-codes/

0 Response to "Bundled Colored Wires Pink Purple White Green"

Post a Comment